The full title of this engraver on Banggood’s site is the

Here below is the mandatory box photo complete with thin “manual” which to be fair is generally in decent English.

On first opening the package, I found this initial installation paragraph particularly amusing…

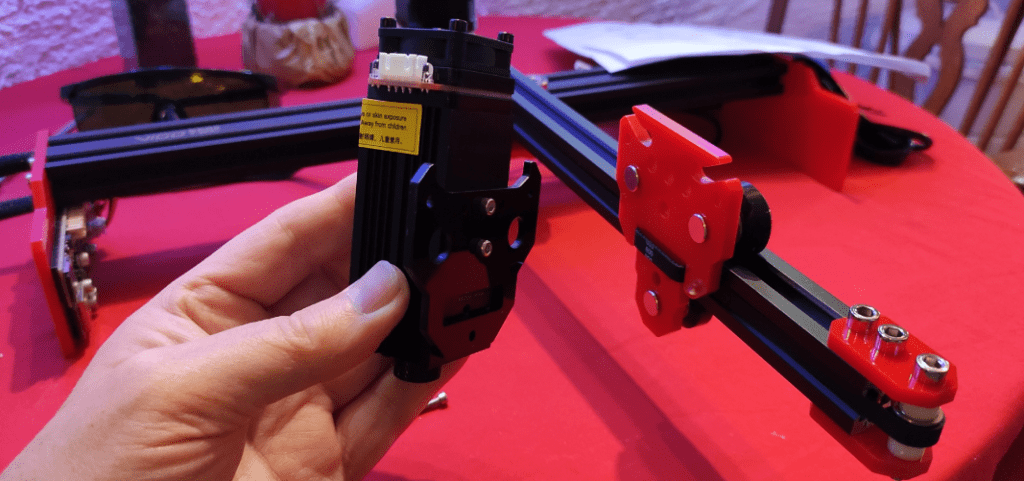

Moving on -this is what you see when first opening the box:

below are all the bits for the engraver minus the manual. Note that pretty green eye protection glasses are included – always best not to lose your eyesight when messing with lasers.

What looked like was going to be a large PCB turned out to be quite tiny, housing an ESP32 by the look of it. Here also are the various sections as I put them together – two ALLEN keys were provided but I needed my own small screwdriver to dismantle the PCB from it’s perspex bracket to remove the backing material.

In case this starts to look complicated, most of it is pre-assembled – there were no more than 8 bolts and 6 nuts – that’s about it – that, attaching two connectors and removing the protective material on the perspex parts.

My engraver came with EU compatible PSU, a USB lead and a small orange USB memory stick. You also get an innocuous looking piece of adhesive foam, use it (in 4 quarters) to put under the base unless your table is utterly flat and solid – best to use this anyway to improve grip.

Before I start, DO wear the green glasses they provide – they fit over existing glasses – very important – this is not a toy laser pointer – it could do you some damage.

There are 3 simple buttons on the left – a black power button then white button A and white button B.

Applying power and turning the unit on with the black button – I started the “low-power” laser option with button A (the first of two white buttons – nearest the black power button). After rotating the laser adjustment ring to get the smallest, round beam, I pressed button B and got THIS on a sample piece of card… trivial but simples….

To get the PC software – I went off to the Vigotec site and grabbed the relevant program – mine is the L7X which means it ~(in theory) has WiFi.

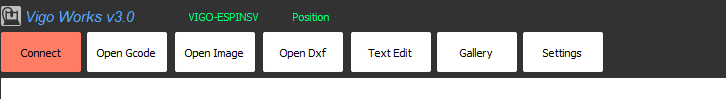

Windows 10 seemed reluctant to run downloaded software from the Vigotec website but it did, as you can see below. Here’s the opening screen shot:

Following instructions, I powered up the engraver with a long press on the black button and that started it’s own access point – I told my PC (WiFi) to hook to that access point. It did. But then the Vigo Works program which by now is seeing the access point:

seemed to refuse to comply, when I hit “Connect” (above left), the connect button momentarily greyed out then went back to “Connect” and at the bottom of the program – the message “WLAN device is close”. What SHOULD have happened is that the CONNECT message should change to offer DISCONNECT.

From there it would be easy to set the engraver to use my local access point instead – but the button would not actually show that it was connected – hence preventing my from firing any commands from the PC. Anyone out there done this already? I can only imagine that “VLAN device is close” means “VLAN device is closed”?

MEANWHILE, not wanting to give up for the night without a result – I plugged in the USB cable to the engraver and my computer and VOILA. We’ll just pretend there is no gaping hole in my desk, obtained while initially playing with the controls.

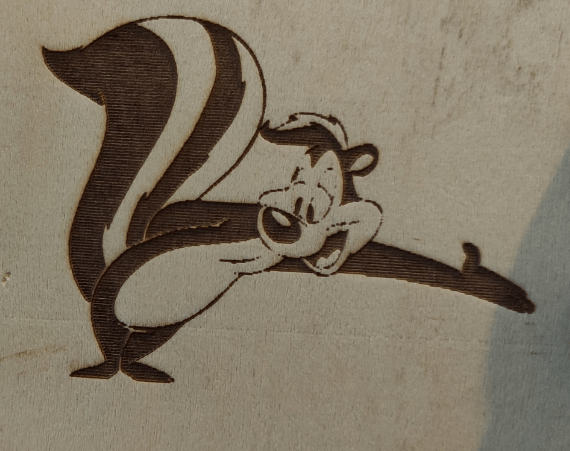

And there is my first engraving using one of the two extremely thin plywood samples that came with the engraver. Even then I noted how sturdy the whole unit is.

Next I found some proper wood for the job – 18mm thick pallette wood which will end up in our wood burning stove – so it doesn’t matter how badly I mangle it up – I’ve already figured out the need to open the window when using this tool. As the laser power is completely variable you can make deep engraving or actual cuts but I’m counting on needing two or more passes to go through 3mm or 5mm perspex or even wood – as the smoke tends to get in the way. No big deal as multi-passes are automated.

Meanwhile I need to get to grips with the apparently troublesome WiFi connection just because USB isn’t always convenient at the other side of the room. I made an engraving that said “Calle Ceuta 14” for our house and for a first attempt at deep engraving…. check this out…

So many uses for a device that can effectively take up very little bench room.

I am waiting for daylight tomorrow to open the window (it is outside cold tonight and I like my lungs in one piece) to try some perspex cutting and more. Ultimately this laser engraver is limted to running with the Vigo Works (now 3.1) software, there simply isn’t enough information to set it up with other packages. Also I cannot get the WiFi to work even with the 3.1 version of the software – and any attempts to upload firmware fail as the relevant tickbox will not “tick”. Having said all that, there’s nothing wrong with the Vigo Works software and you can import a wide range of images. If the engraver wer not at the opposite side of the room to my PC I’d not be griping about WiFi as the serial connection works perfectly.

I’ve been playing around with focus, speed and laser intensity – with good focus on plywood there is very little effect of burning even with deep engraving. You may or may not think it is better to defocus slightly and get a dark burn effect. Well, you can have either. Focussing is done by turning the ring on the lasre with the “weak on” setting so you get a static, non-cutting beam with which to calibrate the focus. Easy.

See the image above – on the right it says “Hi there” snd I’d completely forgotten to focus the beam. At the top is the same thing properly focussed and just as strong a beam, even deeper into the plywood – but amazingly no sign of burn! Ignoer the vertical centre version, a failed experiment and I’m running out of wood.

Note that if drawing text (as against images) you have the full range of fonts normally available on your PC – and to prove the point, I just grabbed “eagle.ttf” from the wonderful DaFont.com website. Here it is below, not an image – a FONT letter. Maybe not the best kind of wood for this demo but we’re in Southern Inland Spain in January – most of the wood is on the fire keeping us warm!! Images below at 15% laser power (it’s too cold to open windows:-) )

Banggood asked me also to mention this other engraver below – note that I have NOT built or tested the Two Trees model below:

— (coupon: BG077AL)

Nice review Peter Thank You.

Hi Peter

You don’t drink wine in Spain? Wine bottles are a useful source of glass?

I guess as your laser is blue(?) you’ll struggle with anything transparent at its wavelength?

Suspect you need a CO2 laser for perspex. Mine cuts 3mm very quickly in a single pass.

There’s nothing like a spot of lateral thinking, Ian – you are of course bang-on – we have some of the best, cheapest and crappiest (next to French) wine in the world here in Spain and we do our best to drink all of it (waste-not, want-not).

Slight technical issue? Bottles being round could be painful to play with – or am I missing the point AGAIN… read on…

I’m somewhat limited here, right now I have only my “20w” LED (blue) engraver. Aidan back in the UK has a CO2 job and my original purple LED laser(4w?) engraver. I’m tight for space here so the key statistic for me was having only 2 sides so it’ll fit in a corner. See the pic. Next weekend we get to go to a big town so I’ll get some perspex no doubt – black would be nice, sensibly I should stick to 3mm? but now thanks to you, I can hopefully destroy the bottom of a brown wine bottle tomorrow after consuming the contents – wheeee.

Pete

Go for 2mm if you can. I appreciate your point re space. My CO2 laser takes a lot of space 🙁

G’day Peter!

Have read all your comments, and those of the other guys.

However, I must be missing something VERY obvious it seems??

I am currently using the Vigotec (blue light!) laser, which purportedly will cut through wood, at least according to the advert which led to my buying.

I have tried MANY TIMES, but without success. Running at 100% laser, quite slowly, (around 350/400 mm/min), and up to 5 passes, but it simply does not cut through 1/8″ masonite board??

The vidoe’s shown when advertised, clearly shows wood around 5 mm being cut, but there are simply NO accurate and specific instructions of how to achieve this.

Any ideas/suggestions?

Looking forward to any replies.

Kind regards,

M.C.

I doubt your laser is really 20W.

5mm into a piece of softwood isn’t a good test, and if you’re doing stuff like this you should have ‘air assist’ to avoid fires.

I wonder if you’ve found a useful vector drawing package? I previously used Corel Draw with my lasers but W10 doesn’t like my old s/w which I won’t buy again.

I don’t like Inkscape & it’s very OTT for laser work.

A cynic I see. Ok Ian I have no way to actually measure the laser output but as it went through something like 5mm of wood at full speed in one pass on 30% I’m not complaining. Accorging to my friend Aidan you should always use multiple passes anyway to get a clean cut if that’s what you need. I will soon try higher power etc to see what I can achieve, but as you say a fan of some description comes first. I have Corel Draw and friend Aidan was going to try sending me a plug-in to handle laser engravers but we ran out of time. InkScape I’ve used – I don’t particularly like it. I’ve always been partial to Powerpoint just because of spending years using it – last night I exported a simple ring and put it into the Vigo Writer library and burned my first hole without issues (took two attempts – the first one – the outline was too thin). I’m still on USB as I can’t fathom why the Vigo Writer won’t do the WiFi – but no matter.

Hi Pete,

I’ve used an Epilog Helix 60W machine extensively in the past & recently bought a ‘K40’ 40W machine for personal use. The Helix was equipped with a massive extraction/filtration device & a BIG air pump.

I couldn’t possibly justify stuff like this at home, however the K40 is enclosed & I’ve attached a Wickes ‘inline extractor fan’ & a large aquarium air pump.

Going back 6 or 7 years I worked with high powered laser diodes (7W) which cost us about £10k at the time. Time marches on, but I struggled with the idea that we now have 20/40W diode lasers for £100.

A little research tells me that it is ‘normal’ for diode laser power to be specified as consumption rather than output nowadays. Your 20W laser is probably 4 or 5W output.

Rather than cutting softwood, a decent test is to see what it does with glass. A 20W laser should etch glass nicely. Give it a try.

I have to disagree with Aidan, I can’t imagine what is to be gained by making multiple passes? I’m open to persuasion.

Powerpoint sounds good but I need to export SVG files. I downloaded Libreoffice today. The ‘Draw’ package looks good but I’ve not tried it yet… Have a look at Tinkercad. You can make stuff for 3D printing & also laser cutting but the laser stuff is quite limited.

Yes, Inkscape is not the easiest to learn, but it is powerful. You should give it a try. Got nothing to lose, it’s free.

The wavelengths are totally different between a blue visible laser diode and a Laser tube using infrared. Glass is transparent to blue lasers and the energy passes straight through. Whereas IR coming from a tube is absorbed by glass and therefore heat is generated allowing for the glass to be etched or cut depending on the laser power output. You need both wattage and wavelength to cut different types of materials, it’s not just about one or the other.

Multiple passes of a cheap laser will cut through a thicker material like craft wood etc, but you need to lower the laser after each pass to get the focal point down into the cut where the material has already been removed. It’s no different to any other optical system, and doesn’t have an infinitely variable focal length.

Just think photography and focus, no different

Hi Ian

My friend Aidan bought a massive device and I think he is wondering if my smaller unit might have made more sense. In our case, “work” and “home” are the same. Someone else passed comment about output versus power – in this case all that matters is results – I am using no-where near the full output and already it seems clear that due to smoke (on palette-wood anyway) multi-passes is the way to go (and a fan). Mind you I have yet to test perspex – I have high hopes of being able to cut 3mm thick perspex for cases. Time will tell.

I have first hamd experience of Aidan doing multi-passes to keep edge resolution – minimising smoke etc. Glass… ok I’ll have to find some – I’m in a small village in Spain – no B&Q here (and thankfully no Home-Depot) but we have a sister company Brico-Depot and we still have lockdown so a trip to Granada is days out of range for now. I guess I could butcher an old RPI-2 case to test perspex – but glass – no.

I just kept hitting the wifi button and it eventually hooked up

Good day everyone!

I have read the comments above, and it seems that others are also not quite sure how to set the equipment up correctly for different tasks?

I have experimented quite a bit with the laser, but I do not seem to get all the settings quite right for CUTTING, let’s say wood, 3mm thick.

I have tried setting the speed at 100mm, the laser power at 90%, cutting “outline” of course, but it did not cut through 3mm wood.

Should one set more than one run to achieve this?

Looking forward to any suggestions or advice!

Kind regards.

If you had a very specific spot on something you wanted to engrave, how do you align up the machine to print in that area?

Could align the part and engraver with marks on the table. Or make a fixture that fits to the engraver and part.

Yup – see other response. Marks on the table good idea, wish I’d thought of all of this before putting that tiny hole in my table – but life is about learning.

The laser has a low power “pointer” mode for lining up the part. Also looks like the software will draw a bounding box in low power before engraving.

Thanks for that. Given that the current price on Bangood was under $300 Canadian, I’ve taken the plunge. Looks like it could be a lot of fun.

I’m reading these comments from back to front in the middle of a blog update…. erm, you can set alignment to centre or top left, top right etc and spot preview in low power (also boundary preview in low power)… I got that one instantly as you have to rotate the laser ring for different height materials… and that reminds me – I just mentioned to Kris in here the idea of multi-passes to make deep cuts – I guess each, say, 3mm deep pass could do with a careful laser ring adjustment for focus to keep accuracy up. I’ll tackle that later this week. Keep up thefeedback – I’m not only blogging this for others, I’m learning as I go. Up to now I’ve been 5mm into a piece of pallete wood without any adjustment – at 40% power – not tried higher than that.

Thanks for the review. Hope the Wifi connection will work.

The Two Trees link is a 404!

Hopefully fixed the Two Trees Link – thanks.