Described as a (Coupon: BG6C7ZG1) – this inexpensive engraver caught my attention over the Christmas holidays and here it is: Normally, Banggood provide brand names but in this case I guess they are branding it as their own product. I note the laser module has tick-boxes for everything from 20-40W. Mine is the 30W (input) and comes complete with green safety specs. February 2021 update: they asked me to point out that they have the unit in both their ES and CZ warehouses.

The kit contains everything you need to assemble the engraver – however, as the provided small manual contains insufficient instructions to complete construction and refers the user back to a video on the website.

“Store provides detailed installation video”

The video itself has no usable sound, only someone humming – and it stops dead around 60% through at which point the user still has no-where near enough information. In case much of this sounds bad — read on – in the end I cracked it and have been happily engraving ever since.

In the photo above from the manual – yes that is a link to a video, yes the instruction is partly in Chinese and yes “more” is the last word. It does look like we have a company or brand name hidden away in there – “Dingqi”.

It has been said elsewhere that Chinese manufacturers tend to state power usage rather than laser output – so – in the data on the Banggood website they state both. The 30w unit which I own has 6.5w laser output power at 450mn. Can’t be clearer than that.

At this point I decided that checking Banggood’s site might be as good idea and sure enough, an ALMOST complete assembly video and three software packages – all in one downloadable RAR file.

Lack of English speech in the video turned out to be NO problem as the person putting the unit together covered every detail and because you can follow the video, pausing as needed, ultimately it took me maybe 3 hours in total to get the mechanics assembled and the video made it relatively easy going.

All the tools needed for assembly are included (essentially three Allen keys) and I ended up with spare nuts and bolts etc.

Right now I’ve been spending a lot more time than usual doing reviews and generally tinkering (what else would you do during lockdown) and so I’m incredibly short of room in my office and workshop. Because of this, the laser engraver was largely constructed on the floor and a stool – which gives you an idea of how (relatively) simple the whole procedure was as I managed it without losing anything! However, it will be obvious below that fitting the wiring and control panel was a minor challenge due to less than obvious information:

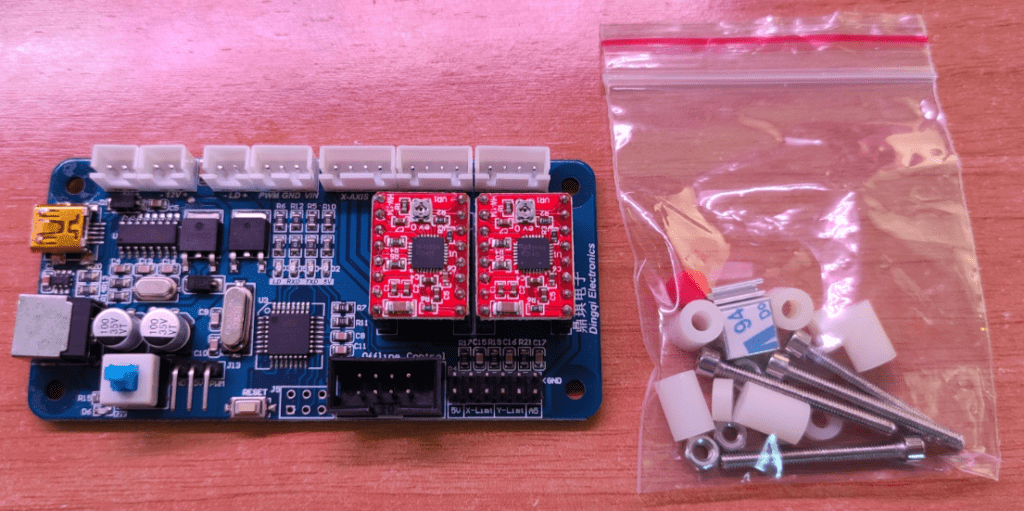

In the photo above, you see the pre-assembled control panel – this simply plugs into the power supply (power connector lower left) and PC (mini-USB connector upper left). What is no-where near as obvious is… what on earth do you do with that bunch of bolts, nuts and spacers?

Once I’d assembled all the other parts, I was left with three pieces of plastic – the smallest of which was broken. Of the other two, the larger of the two looks like it could be meant to help mount the control panel onto the front of the engraver.

Something like 3 hours or so after starting this project I appear to have all the hardware assembled.

Note the control panel on the front – and no, I don’t have a clue what to do in order to tidy up those wires. As long as I’m making small samples I don’t suppose that matters too much.

There is no guidance anywhere as to what to do with the sprawling control cables.

When it comes to the wiring, I did not anticipate any major issues as there are basically 4 leads to connect (x, y1, y2 and laser) plus power supply. What does cause me slight concern is the mounting of the control board itself which apparently mounts on the frame and comes complete with several bolts, spacers and two heatsinks but zero instructions as to what to do with these parts!

Actually that’s not entirely true as one of the first photos on the Banggood site hints at the control panel mounting and the two black perspex parts I’ve been trying to find a use for – I wish I’d seen that before assembling the whole thing. Right – done – assembled. Now to figure out what to do with it.

I turned the power on – and there appeared a large red cross – that’s a start…

This engraver connects to the PC via USB (there is a miniUSB connector on the control board). As for the laser itself, my other engraver, the Vigotec laser engraver needs simple visual laser adjustment for different material depths. This time around:

“Engraving can be done without adjusting the focus; The new laser can combine both precision engraving and high-energy cutting at the same time. The laser power of the fixed-focus laser is more stable than the zoom laser”

Not sure even now I understand this “automatic adjustment”. The first question I have is: If this is automatic, why do the files on the Banggood RAR file include a file called “laser engraving instructions -e.doc” which says:

“Turn on the weak light, it will appear a point on the work piece. Then swivel the knob to adjust the point to the smallest.”

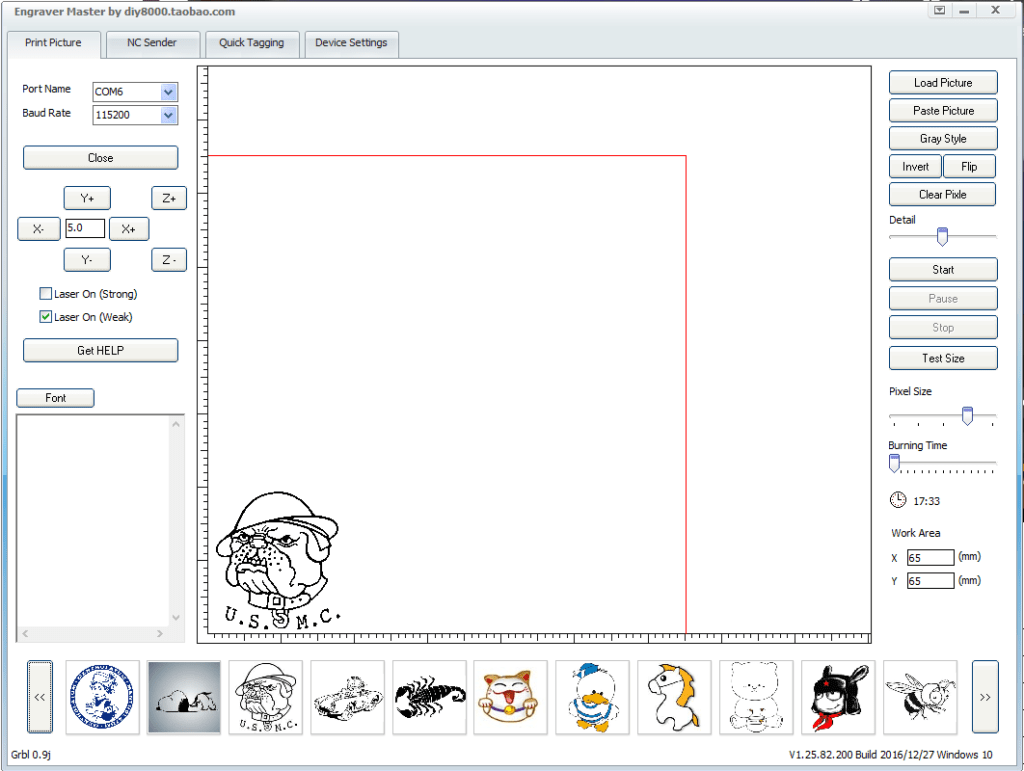

Software

I note that the software in that Banggood RAR file includes CNCbox (by the look of it, only Chinese)

Secondly, LiteFire which is in English and does talk to the engraver – I had to manually select the COM port at which point the program responded to “open the larser device” – my spelling here is not an error – theirs is. I’m not missing any steps here.. I plugged in the laser via USB, the program noted that COM4 and COM6 are in use – I tried COM4, it bombed. I should have known better as I have an ESP8266 on COM4. So I switched to COM6 and all was OK. No driver installs, no setup, nothing.

Finally: LASERGRBV3.0.10 (updated online as soon as I ran it for the first time – still no idea what it does but it talks to the engraver – oh, with no drivers installed or anything else, I could get the program to move the laser around – can’t see example files)

I’m beginning to wonder if someone has, without a clear idea of what they are doing, cobbled together software from various free sources…

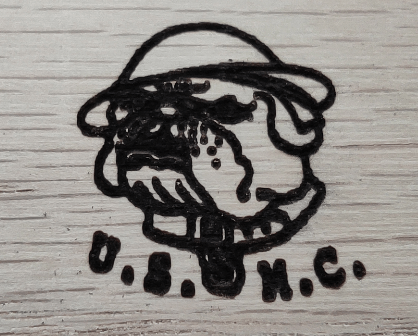

I do think I’m on safe ground griping about the documentation, if it was good I would not be stumbling about in the dark here. I think I have the unit on the lowest setting but am actually doing reasonably deep engraving into plywood – my last engraver made it quite clear that the low setting would not engrave anything but was for line-up only. If these crosshairs actually shone where the laser shone – then I could see that such a low intensity setting would not be necessary. See above the line of dots – no-where near that red crosshair.

Now, here’s the thing… not having ANY information to check if the laser is auto focusing or manual – I just started the ball rolling on “Laser On (Weak)” – one of two power options. Well, it seems to me to be pretty powerful for a “weak” setting. There is a set of cross-hairs – which unlike the laser are not entirely in focus – and I’m not even sure of the point of them – surely you might expect the centre of the cross-hairs to be where the laser will burn?

What you are looking at above is 5mm thick plywood, The image is 25mm * 20mm and the engraving looks to be maybe 0.5mm deep. The largest image this engraver can handle is 40cm*38cm. At this point I’m hunting around in the dark wondering if anyone knows any more than me about this engraver. Sure, it works – and seems to work without any setup – but I can’t help the feeling I’m missing something. That’s an observation, not a complaint. I’m having fun.

RIGHT – NOW WE’RE COOKING. My initial impression as I stumble about is that here we have a nice piece of hardware. The Program which loaded up under the name “LiteFire.ex.exe” is, it seemed, actually called Engraver Master by DIY8000.taobao.com (turned out to be made by BatchinMaker?

http://my.bachinmaker.com/wikien/doku.php?id=engraver_master

Right now it is printing out the second sample image I’ve tried. If you look in the accompanying 3-page documentation, it says the software is called “Minilaser” – how’s that for confusion. In the original software (2016 version) software itself is a help link “http://123.249.29.246/wiki/doku.php?id=Engraver+Master” – which doesn’t work. Note the date on the main page of the software:

Then I stumbled upon this link. http://my.bachinmaker.com/wikien/doku.php?id=engraver_master and that has a 2017 date…AHAH. SETUP.EXE from that link: “2020-04-23 Windows 10” – THAT’s more like it. I set WEAK LIGHT ADJUST to “1” – looks pretty powerful for a weak light to me… smells it, too and unlike the original software, that was less focussed.. it turned out that I needed to manually focus by adjusting the distance to the wood – eventually I’ll figure out a better way to adjust focus. I’m not seeing a focus ring.

The partial image of the dog is sharp, this new horse (or whatever it is) looks blurry? I need more wood. I’m on a learning spree now. The laser is definitely not “auto-focussing” – and “laser on (weak)” didn’t do anything out of the box – however it is easy to adjust the laser in “settings” from 0 to 100% – I originally had it set at 100% and somewhat out of focus. At 1% it is easy to check focus and I’m trying 20% for engraving.

In the above series, I’m happy with that 1% laser – no notable burning at all. At 20% the output overwhelms my phone camera and my eyes (through the supplied green safety glasses) but the image you saw above now engraves in the plywood nicely. I’m guessing 0.2mm line width and 0.1mm depth.

I do seem to have some restrictions on speed – probably just down to the documentation or lack of it. For the sake of it I tried the free software “Laserweb 4.0.998” which stated that the “firmware grbl 0.9j” was detected and that I should have at least version 1.1e. I took a chance and clicked on firmware upgrade in “Engraver Master – this upgraded the grbl to 1.1 at which point on testing Laserweb, the dialog said “No supported firmware detected. Closing port COM6” but at least now, back in the “Engraver Master” package, “Laser on (strong)” and “Laser ON (weak)” now work – so that’s a plus – and by adjusting “burning time” I get some control over speed.

There is a small aluminium cylinder which I still can find no use for.

I need more WOOD. Meanwhile for those of you wondering about the significance of 450nm, the wavelength of the blue/violet laser light. 450nm borders violet and blue on the spectrum with red at the other end centered around 695nm and green in the middle.

Comparing the Vigotec and this anggood-branded engraver with my original Eleksmaker A3 Pro Laser Engraver (early 2019) there are points in favour of each – the Eleksmaker DOES run standard 3rd party software and I hope in the not-too-distant future to take a look at an updated version of the latter – but the first two are in fact pretty straight forward to use and certainly for beginners there’s a lot of fun to be had with either model.

I recently acquired a 3000mW Blue CNC Laser Engraver from Universal engraver that has the exact same control panel circuit board as yours had. Since the company failed to provide a proper assembly manual (or at least one that had the right control circuit board, I am curious as to which plug port you used for the laser power converter (i.e. the grey box connected to the laser itself. Forgive my terminology as I am not a mechanical engineer). Is it the 5V, 12V, or one of the other ports? I have included a picture for clarity. Any advice on this would be greatly appreciated!!

Hi, I have a request too: I bought a laser engraver machine that looks identical to yours. I accessed the link in the book, but it’s in Chinese; I partially translated with Google, but I can’t download the assembly video or the drivers. The link sends me to register with Baidu and I can’t do that with my phone number from Europe – Romania. So I have no installation instructions or drivers.

Can you send me a direct link where I can download them? Or can you send me the RAR file, on Wetransfer, or something similar?

I never used an engraving machine; I hope to manage, if I manage to mount and install it; your article is very interesting … but scary at the same time .. :))

I downloaded the RAR file from here – https://drive.google.com/u/0/uc?id=13ajc00BK5USPAwAl7e6L6uc1sqcKbCay&export=download

Hello all

I‘m working with the free LaserGRBL. I realized, that engraving a grayscale picture gives a bad result as the laser light power is not really controled by the grayscale. It is more a control by pixel density and power on/off. With the 30W laser version, this is to strong. LaserGRBL has a possibility to switch to light modulation modus but it needs grbl 1.1 firmware instead 0.9j. So I downloaded the grbl hex file v1.1h (2019-08-25). Saved first my grbl settings and installed the sw XLoader. Turned off the controller board with the red button to stop the fan. With XLoader selecting the hex file, the active com number and arduino nano atmega 328 (the board seems to look more than a nano, than an uno), then speed was automatically set to 57600 or so (Not 115200), short prayer and then upload. After finishing I started LaserGRBL again and … yes, it has firmware 1.1h. Now, I reloaded my settings. Changed there Laser Modulation to 1 and safed it to the ic memory. Finally, changed during picture loading the selection, just below laser speed, from constant power (M3) to modulation (M5). First try to engrave a picture and wow …, I am happy. It is much better! Full success (Puh, I realy was afraid it would not work anymore 🙂 )

Right, I’m just giving up for the night but will replicate what you’ve done, this week. Thanks for the feedback. Actually I just realised I’m on the latest software as it is..

Hi Peter,

What about the aluminium heat sinks? I was struggeling where to place them. For the motor drivers they seem to be to big, risky to touch other parts . Finally, I placed them on the transistors and the IC next to them on the upper left side of the board. Not sure if it is correct, but the risk is the smallest to get any circuits shorts.

Hi Peter, thank you for your article. I’m in the same situation as you, I have bought the same 30W laser engraving as you have and is now trying to figure out how it works.

I have a guess about the small aluminium cylinder. Maybe it’s meant to be used for adjusting the distance between the laser and the object to be engraved?

I have not come so far yet that I could test this. I’m right now stuck with another topic, the laser does not turn on at all. I have found two (!) buttons on the top of the laser. I guess one of them is for the power to the laser but what is then the other for? Do you know?

I’m not sitting in font of the machine right now but I’m almost sure one is power, the other low-high? Either way the machine works – my only issue up to now (bearing in mind I’ve been unable to get materials for PROPER testing – just finally got some wood and plastic at the weekend) is that the machine does not seem to work with standard software out there (Lightburn for example). Having said that, the software supplied works ok.

Hi Peter,

In regardes of the small electronic board on top of the laser, one button is for turn on/off the red cross laser, the other is for turn on/off the blue laser. And yes the aluminium cylinder is for focus distance check.

When using the laser for cutting acrylic, does one need to place something underneath the acrylic like plywood? I have a 3018 with an aluminum table/bed.

I would put plywood underneath, having put a tiny hole in my desk already.

Thanks Pete. Having a hard time finding info, as most of the info is for engraving. I want to cut thru 3 mm of acrylic. I’ll tape it to a piece of wood.

Feel free to feed back any results- when my wood and acrylic finally arroves from China I intend to have a go so any tips most welcome.

focus is very important on those diode lasers as they tend to have short focal lengths so if you’re off by over a few mm then your lines are fat and energy spread over wide area means little burn depth.

I’ve got a K40(CO2) and an Ortur(diode) and LightBurn is very nice software. free for a month and then well worth the low cost after that. BTW, my K40 cost US$350 and Ortu LM1 15W US$179

R: focus – see my March 2022 review of the NEJE Master 2S https://tech.scargill.net/neje-master-2s-30w-laser-engraver-and-cutter/ – that laser has an incredibly long focal range (ie height range where it remains in focus. Good enough to ensure sharp focus while cutting through 3mm acrylic – short enough to ensure when the piece drops out of the bottom, the floor doesn’t burn 1 metre below 🙂

Seems like a fun, albeit terrifying, toy. For the software, is it just a generic GRBL-ish controller? I would think you could use it with any of the software for controlling GRBL lasers like LaserGRBL or LaserWeb. That’s what I did with my cheap mill engraver, I have zero trust in installing the software they send you. I threw it away and used bCNC.

Hi Jason

I just tried LaserWeb – response was “grbl 0.9j detected. Grbl version too old – you must install at least GRBL 1.1e. Machine disconnected.”

Thoughts? As I don’t seem to have a brand name for the machine, no idea at this point how to upgrade the grbl firmware.

It’s likely just a standard Arduino-based CNC controller board running GRBL that you could update using the generic GRBL build. GRBL itself really isn’t machine specific, you flash it and then can configure the specifics of your machine. There is a gcode command that dumps the current GRBL config, you would need to copy that and save it, use the Arduino IDE to flash a newer version of the GRBL firmware, then reapply the settings you saved to configure it for the machine. https://diymachining.com/grbl-update/ is a good starting point for instructions. You would want to keep the laser disconnected or wear your laser glasses the whole time just to be on the safe side in case something weird causes the laser to turn on.

Doing the upgrade is not without risk, however. It’s possible (albeit unlikely) that the manufacturer is running a modified version of GRBL. As a fallback you could use avrdude to dump a copy of the firmware that is already present as a backup in case you can’t get the updated firmware working.

*If* everything goes well it should be fairly easy. If things don’t go well you probably wouldn’t ruin anything, but it could take a decent bit manual tweaking to find the correct settings for the updated version of GRBL. Whether or not it’s worthwhile is a trade off between getting a bunch of new features and a much better interface versus the risk of it not going smoothly and you having to tinker with things to get them working. When I upgraded my engraver I went through a very similar process and ended up learning a lot about how CNC controllers in general and my machine specifically worked so it was worth it for me.

I read somewhere that they ARE running a modified version. Mind you, I just upgraded it. All seems ok, it’s a tad slow as I cant seem to get full control of speed – but other than that (see toward end of entry) I’m not unhappy with it (given that I’m something of an “engraver novice” anyway).