I LOVE getting new toys. The original Zajia was sent to me in January 2020 by Banggood and it turned up in the UK in February. The battery-powered, USB-charged Zajia clips straight into the tap in the kitchen or bathroom to provide proximity-controlled water. If you are on a water meter or just environmentally-conscious – this device might just be for you.

As you can probably tell in this article generally, back in February the health positive implications of this device had not really occurred to me – but in May 2020 in the middle of the pandemic, it seemed absolutely sensible, even essential, on returning home after shopping, NOT to touch ANYTHING in the house BEFORE washing hands. As you will see elsewhere I also obtained an automatic foaming soap dispenser to go with the Zajia which is now only on it’s second charge.

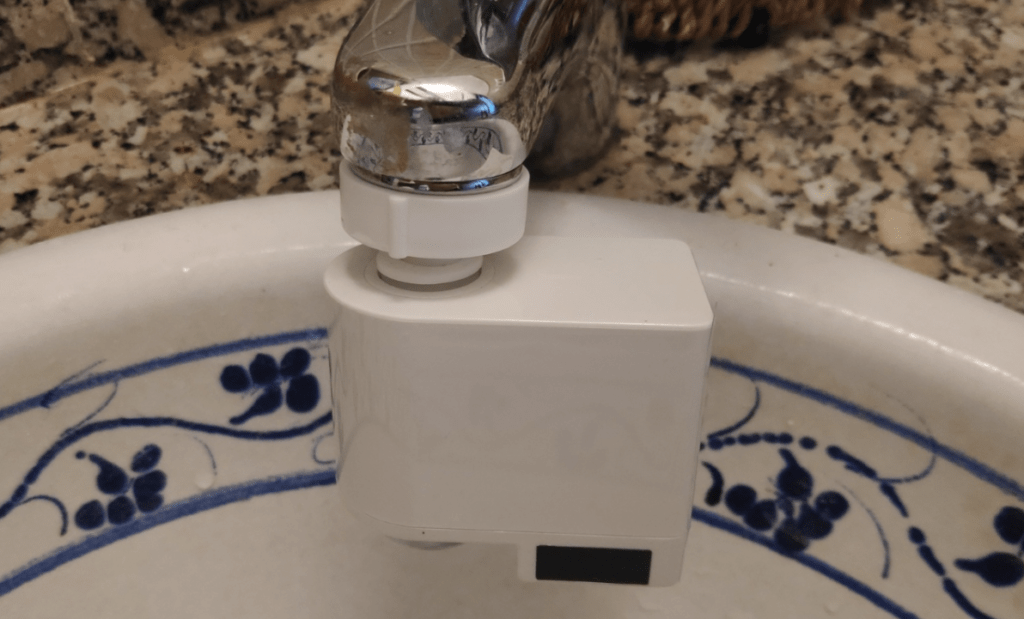

So what’s new? It is now September 2020 and I’m now in Spain and I have a second unit which I’ve just fitted in our bathroom here – works a TREAT with no leakage. This time I put the IR on the FRONT. This took seconds to fit to the tap.

The comes with a range of (plastic so no rusting) tap adaptors and takes seconds to slip onto the bottom of any mixer tap. I don’t bother to turn off the tap as the device has zero leaks, instead, I just leave the tap mixer set to the kind of temperature I usually need for handwashing etc.

The Zajia has proximity sensing on the underside for a short burst of water as required and another on the back (or front as you prefer) for constant ON or OFF. Just put your hand, toothbrush, razor or whatever underneath the Zajia and out comes the water. It’s all very intuitive – so that I could not tell you if it came with instructions or not – certainly didn’t need any.

When the device arrived last week I lifted the grey flap and plugged in a USB supply to give it an hour’s charge – and that’s it, the device has been in constant use ever since. Now that I’m used to it, I hate using taps that don’t have similar devices. I fitted this in the kitchen to test initially and then into the smaller of our two bathrooms – the only thing wrong is that I now need two more for life to be complete again. The Zajia doesn’t seem to get in the way and doesn’t get dirty as of course you don’t actually touch it. Needless to say it is waterproof.

If I were to improve the device I’d add a temperature sensor and third proximity sensor to somehow detect how hot or cold I wanted the water to be – but I guess that’s stretching things a little.

Peter, I was fascinated by alternative heating solutions and so I went on proper training courses for ASHP’s GSHP’s, solar thermal and solar PV and I hold nationally recognized qualifications in those 4 technologies.

My most recent job was a new build passive house of 200 square metre floor area heated by UFH and a Samsung 9 kW ASHP. With an outside temperature of 2°C the system raised the internal temperature from 14°C to 19°C in under two hours. I did all of the heating, plumbing and control systems. The house also has a heat recovery system on the ventilation side. BTW I am approximately the same age as you.

WELL that might be helpful… actually a couple of months ago I got LG’s own engineer out and he confirmed the system was running at half mast – apparently to keep the noise down – we have no next door neighbours – so now it runs at full steam and is much better but at -5c outside it struggles. I can only imagine the reason the company did not fit a larger unit was PROFIT… themostats – my requirements are a little awkward – solid stone walls so limited range, my own WIFI stat sorted that out, holiday rental for part of the year so I need total control remotely but want limited control locally… (learning does not apply when you have constantly changing holiday customers) – on the other hand, guessing forthcoming outside temperature changes 2 hours before they occur is on my horizon. I can have the system compensate even givn the 2 hour+ heating response time. VERY different to running an oil, gas or forced air system as you will know. Very occasionally my control relay fails – the LG switching unit makes a switching noise and I suspect lots of electrical noise but have nothing to test that with… (my access point isn’t failing so I’m pondering a VDR on the relay contacts….) – thoughts… I would also like to automatically shift the heat to the bedroom end of the house at night and away from it the rest of the time (not multi-zoned). Any recommendations there for radiator control valves (battery powered and WIFI) welcome.

If I understand you correctly when you say ‘my control control relay fails’, i take that to mean a device you have made using a Sonoff or something similar rather than an integral part of the LG system. I have seen an issue with an ESP32 in circumstances where electrical noise was present. A VDR might help but I would also consider two other options.

If possible I would change the mechanical relay for a solid state device and secondly I would site the relay module away from the ESP8266. To achieve the latter I would Tasmotize a Wemos Mini Pro and put that well away from the LG unit (electrical noise and large mass of metal), I would then use an opto isolated relay unit local to the LG. Most decent SSR’s are inherently opto isolated anyway. Why a Wemos Mini Pro? Well because it can have an external antenna which will increase its ability to receive weak wireless signals.

Regarding the radiator control valves there are commercial devices made by Honeywell and Drayton Wiser that are battery / wireless units but I believe they use an in house wireless protocol and I don’t know if they have been ‘hacked’ I have got some Drayton devices I could set up, but I have no means AFAIK! of looking at the protocol.

If the radiator in question has a TRV then you could buy a thermo-head for an UFH manifold and fit that to a standard TRV body. You could then use a Sonoff to operate it. You can get thermo-heads in 12 VDC and 240 VAC, the latter would be easier to use with the Sonff I guess.

I’ll see if I’ve got some bits lying around and try a thermo-head on a standard TRV

Finally, plenty of thick stone walls in properties I work in!

Noooo, don’t stop – I make awful mistakes when responding – I’m just good at adding in corrections later. We’d miss your comments if you stopped. Erm, can’t you edit your comments? I can (but that’s probably as I’m admin)

I do not want to use Peter’s blog to discuss the technicalities of heating and hot water systems but there are a few point worth clarifying:

Legionella bacteria are killed, if present, at 60°C. ASHPs cannot achieve 60°C or even 55°C without supplementary heat input from an immersion heater. I am most familiar with Samsung ASHPs and they have a once a week sterilization cycle which runs overnight and heats the water in the cylinder to 60°C. I would think Peter’s LG ASHP has this function as well.

Modern hot water systems use unvented cylinders so there are no cold water storage tanks.

Cold water taps on basins or sinks should never be connected to storage tanks. As alluded to in my original post there are two types of mixer taps, if the tap is the type where mixing occurs at the tap nozzle then the cold water, if mains supplied, is safe to drink.

The local hot water units I referred to are small tanks holding 10 or 15 litre and connected via a non return valve to the incoming mains cold water. They have a 2 or 3kW immersion heater and only heat water in the tank to the level set on the thermostat. As water is drawn off they heater turns on again and re-heats the water. The cost to heat water in this way is no more expensive than running the immersion heater in the ASHP to raise the temperature to, sat 55°C, since the cost to heat a given volume of water is the same whatever the storage vessel. Since this local 15 litre is sealed, there is no legionella risk and so for a bathroom basin the temperature can be set to around 42°C. If the property is on a water meter it saves water too because no water is run off until the hot water arrives.

My LG system DOES in fact to a weekly sterilization – I’d forgotten about that. Nice to come across someone who understands Air Source systems – the engineers who fitted it were clearly struggling but that’s another conversation.

One possible issue with having the mixer open, is that you could end up with the hot and cold pipes mixing. It won’t happen quickly, but you could end up spending more because the hot water in the pipes circulates into the cold. Probably not a significant issue, but worth considering.

Good point and thanks for that. I wonder if anyone else thinks that is significant. I’d imagine the mixing will be very little if any. In my bathroom tap it always has taken ages for hot water to come through so any pre-mixing would be welcome 🙂

The funny thing is that you could actually do this deliberately, to “preheat” the tap, so to speak, without wasting water. By putting a pump on the cold side of the heater, and linking the hot pipe back to the cold, you can actually force flow in the hot pipes, pushing the “cooled” water back into the cold pipe. The down side is that you may end up with hot water in the cold pipes, that surprises you when you only want cold water!

That is, assuming you don’t already have a hot water return pipe in place.

https://www.grundfos.com/service-support/encyclopedia-search/hot-water-circulation.html

Rogan, in the UK your proposal to ‘force’ hot water into the mains cold water supply pipe would be a breach of the Water Byelaws and potentially dangerous. If any tap or device attached to the tap causes the hot and cold water to mix within the tap body then both hot and cold supply pipes are required to have a non return valve fitted in the supply pipes.

In Peter’s case if the issue of hot water reaching the tap is significant, then a secondary hot water re-circulation system could be installed. There are a number of significant factors to be considered with such a proposal and it is a job for a professional installer.

A simple solution is to fit a local 10-15 litre electric water heater connected to the cold supply. Very effective, very efficient and simple. It is also cheaper to install than a re-circulatory system.

Today I learned 🙂 Fortunately, I’m not in the UK, although I realise that Peter is. Just to be clear, I’m not suggesting “forcing” anything into the supply entering the house, but rather simply allowing/encouraging the “now cold” hot water to circulate within the house back to the geyser, drawing warm water from the geyser into the pipes.

A small water heater part way along the pipe is an interesting alternative. Having recently renovated my kitchen, I had a plug installed under the sink, for a future “instant heat” option. I was not aware that such small “geysers” are available. It may be a better alternative, although it would probably consume more electricity long term than an on-demand heater would.

Any such system would provide hot water at considerably more cost than our existing heat – which is an air-source heat system which powwers the central heating and also keeps a fairly large hot water tank at 55c. I do rather like the idea of an inline heat-on-demand setup as long as it would know to turn off when the incoming water reached working temperature. It would also be handy,if this saw that the hot water was NOT forthcoming from the heating system, to turn on the 3KW emergency immersion heater that normally does nothing unless turned on manually. I guess I should get my act together and have that come on if the top of the hot water tank is less than, say 40 C.

I think the UK solution to “long run time before hot water arrievs at the tap” is a recirculation pump and return pipe. At peak times and in houses/buildings with lots of people, a electric pump (same as a British Central Heating pump runs at a low duty cycle (say for 1 minute every 5 minutes) for 2-3 hours on a daily basis to circulate hot water down the normal hot supply pipe to the furthest part of the building just short of the furthest tap. The unused hot water is returned back to the storage tank by a return pipe. This obviously required extra plumbing, but is often used in large bungalows or motels (think of a typical Travelodges – a long thin building with lots of long pipework top the furthest rooms from the boiler room)

Circulating the hot water by pump before it’s needed charges the pipe almost to the tap with piping hot water. Flow rate need not be very high at all for this and heat loss is minimal on properly insulated pipes. This pumped circulation system can actually reduce energy bills even with combi boilers.

This because running off 1 minute of full-bore water into 22 or 28mm pipes means 1 minute of cold water is entering the system. By the time the hot “slug” of water hits the tap top please the user, the long pipe is charged with hot water – the loss occurs when the tap is turned off and over the next half hour, the water cools in the long pipe and goes cold again. Then the next user comes along, does the same, rinse/repeat (literally)

Having the pumped circulator means the tap is only on for 5 seconds, providing hot straight away, so is turned off straight away.

Savings are greatest in larger diameter hot pipe systems, so 28mm or 35mm hot feeds to motels can save quite a large volume of water expecially when people arrive/depart the rooms almost around the clock (typical motel coming and going pattern). It’s also more common in cold arts of the world, eg: Scandinavia, Siberia Russia, where temps are lower so losses in pipes are greater as they pass through unheated voids in the building. (it’s all about Delta-T and all that heat tranfer maths stuff ‘innit)

Also re: your relay switchiung problem – you may need an RC snubber on the relay contacts, and make sure there’s a back EMF diode on the relay coil itself.

You can usually help anomalous spikey stuff on power rails by adding more capacitance, within reason, say a 470uF electrolytic capacitor (with correctly oriented polarity) across the DC supply rail. More if your PSU can handly it – note the extra capacitance causes an inrush when turned on so don’t go crazy.

For exmaple, I add a 470uF 12V capacitor across the supply rail of a Raspberry Pi or Orange Pi for normal use just to prevent glitches – 1000uF or 2200uF caps for industrial use (with a beefier supply I now can handle more inrush) This smoothes the supply more – anecdotally this can possibly increase the life of the PSU itself and reduce SD card write errors but I have no hard figure on that, only hunches)

Note that any electronic modules like DC-DC power modules can suffer in a hot environment (boiler control panel area/cupboard/hot cabinet)- typically the electrolytic caps dry out and partly fail – causing power supply glitches.

The main reason I do not have mixer taps in the kitchen is that stored hot water is not safe to drink unless boiled and therefore there is a risk of contamination if someone draws a glass of water not realising the mixer is partially open. This also applies to any cold water taps fed from a loft water tank (usually upstairs in older UK houses). Any residents of houses which have a loft tank from prior to the 1990’s and therefore before the requirement for Byelaw kits may be horrified to find the range of contaminants (animal and insect) that can be found floating in these open tanks from which they are drawing water to clean their teeth and bathe. Also the recommendation is that all stored hot water is heated to 60C or above to prevent Legionnaires bacteria. Sometimes you are happiest when you don’t look too carefully.

Hi Steve

It seems that no-one told the air-source heating people about the recommendations. The recommendation WE have from the Air-Source people including LG who’s Air Source system we use, is that the hot water is NOT to be heated above 55c. (UK).

It’s sometimes hard to know how much risk is involved with ignoring some of these recommendations. Whilst it’s true that the Health & Safety Executive stipulate 60C or more for hot water storage they also state that cold water storage be kept below 20C – how many people have any way of achieving that is likely to be minimal.

How long between recharges I wonder?

Perhaps in the next version they could use the running water to recharge the battery.

Good point.