The certainly has possibilities – but unlike my Crealty LD-002R who’s operation was immediately obvious and which works very well, the starting point with the Anycubic back in November 2020 suggested I had a faulty unit – as I develop this blog entry and associated videos, it will all hopefully become a lot clearer – I still think Anycubic support are rubbish – but as for the machine itself – I LIKE IT). I wrote most of this (initially negative) blog entry near the end of 2020 – but persevere to see the MARCH 2021 updates at the end.

The printer makes use of a built-in 6″ 2K monochrome LCD to selectively set resin, layer by layer. I originally put together a short “unboxing and switching on” video and spotted an issue with one of the main menus. See below…

I immediately noted that the 3-page short assembly instructions that come with the printer are just enough to get you started – but the manual and other docs are readily available as PDFs for downloading as you will see below!!

The basic printer arrives ready to go but with no resin and no spare plastic (FEP) film for the resin vat. Banggood supplied a pack of 4 FEP films which I’m keeping handy in case I need them. I suggest immediately obtaining 500ml resin and at least one spare FEP sheet – I discuss this here.

Banggood, AliExpress, Amazon and others all supply a range of resins – I wish I’d known that when I got my first resin printer – you can easily obtain “Standard” and flexible resins and that’s just the start. I only used the standard resins originally – handy for models and cases for my gadgets but right now I’m using Elegoo clear blue water-washable resin and I love it – no need for isopropyl alcohol to clean everything.

One trick I have picked up is – hollow out your model if it does not need to be solid – you’ll save a fortune in resin and the end result will be much lighter – that is a subject all by itself.

Pretty much as with the Crealty LD-002R and H which I’ve already reviewed, with the Anycubic Photon Mono you get three sets of gloves, some paper funnels, a mask (in 2020/2021 the company probably figure you already have a house full of masks) and two scrapers along with three Allen keys. The Photon Workshop “slicer” software is easily downloadable for MAC or PC as is the manual for the printer itself – along with an update for Photon Workshop. This link contains links for the lot. I could not originally see any working FIRMWARE update link in the manual – just a rather useless [Newest] in the manual – no link. Read on…

Right now it probably sounds like you have everything you need included apart from resin – but there is one other item you may wish to consider – protective glasses. No need to worry about the UV light because the yellow cover will take care of that – but these resins – until “cured” are somewhat toxic – hence the gloves. I wear prescription glasses and like to live dangerously but I’d seriously recommend safety glasses – that’s all I’m going to say on that subject.

Curing can be done with sunlight or (as you’ll see in my first Creality blog entry) you can use a LED UV Curing Lamp – or both.

The Photon Workshop manual allows you to save standard .STL files as .PWMO – the file format used by the Photon and the manual gives examples of simple conversion from .STL 3D files as you might find on, for example , Thingiverse to something the printer can use. Anyone new to all of this will want to start with off-the-shelf model .STL files as I did. An example file is supplied on the included USB memory stick.

When I received my first Crealty printer, it, too, came without resin and if you look at the relevant blog entry it tells you what resin I bought off the shelf – I have both cream and clear red resins, neither of which are Crealty or Anycubic products. I also have some Anycubic-branded “405nm Resin for Photon 3D Printers”.

By mid-December 2020 I’d had had three attempts at printing my first model from a .PWMO file using two different resins including the cream resin I used successfully on the Crealty printer.

The Anycubic Mono comes complete with a memory stick and the free software Photon Workshop which as suggested above, effortlessly generates .PWMO files from standard .STL files – a .PWMO file can be copied to the stick and the latter then plugged into the printer. I know because I tried it including hitting the HOLLOW button in Photon Workshop before saving the slice file which then went straight to the printer.

For my first test I took a “cable manager” .stl file and an “efreet_sultan” .stl file from Thingiverse and made a single .PWMO file comprising three cable ties and the sultan as a test – that was to take 3 hours to process. At this point I had not yet found any firmware update for the printer and there was something wrong with the menus – If I went to TOOLS – I would sometimes get to control the platter or may be sent into file selection.

The on-screen BACK button did not seem to work properly for much of the time. I felt sure this was down to firmware and at least PART of that issue seemed down to what felt like a resistive (rather than capacitive) touch screen. Finger-nails worked better than finger ENDS.

But then I had a much greater problem than dodgy menus. I printed the combined set of cable ties and the little guy you see below – leaving all settings at default and ensuring the package was set to produce results for the Photon Mono. As you can see, the resin was also by default set to BASIC. (The resin price you see (below right) is arbitrary, ignore it).

After 3 hours I returned to the printer to discover the printing was nearly done – all except for the minor problem that there was no print. Instead (and I am cutting a long story short including the smell of resin and a lot of isopropyl and kitchen roll) I found that there was absolutely NOTHING on the metal printing plate and only a fraction of a millimeter of the start of the model sitting solidly on the FEP sheet – which thankfully turned out to be unharmed.

For the “efreet Sultan” I thought possibly that the bottom of the model was not flat, this would account for failure, if the model drops off the plate after a fraction of a millimeter, that will stay on the FEP sheet and not continue to develop. The cable ties however were perfectly flat – and positioned correctly and hence should have worked, instead a super-thin layer of them ended up on the FEP sheet with nothing on the metal plate.

I am SO glad I’d already done all of this with the very successful Crealty Resin printers or I’d be feeling suicidal at my failed first attempts with the AnyCubic.

I did of course check to see if the Chitubox software supports this printer – while it did support some AnyCubic printers, when I made these models it did not yet handle the Mono.

What you see below is the first 1mm of what should have been 3 cable ties and a model maybe 70-80mm high. What’s there is rock solid so there is no doubt the actual screen turned on. I also did a quick check after I’d cleaned everything up..

As you can see below – the FEP sheet emerged unscathed after I carefully removed the failed print (fingernails). As you can imagine, at the time I had no explanation as to why 3 hours of motor whining and correct looking movement produced only this. The resin I used was my new “LONGER Standard Rapid PhotoPolymer Resin for LCD Printer (colour: clear red; wavelength 405nm)”

I THEN tried the same again (but a simpler output) with the CREAM Weistek resin that worked so well on the Crealty. Same result – nothing.

I did of course contacted Anycubic (on several occasions) and Banggood (who supplied me the printer for review so I did not expcect or ask for support from them) about this to find out why the menus were an issue and why the prints failed. Anycubic support promised to send a replacement LCD and front screen and (mid-December 2020) failed to deliver ANYTHING. I didn’t ask for a screen – they just offered then failed to deliver.

Meanwhile I managed to get the free version of the independent Lychee Slicer (v3) which, given a demo model, produced yet another thin slice of useless resin using the AnyCubic while producing an outstanding result with the Crealty LD-002R and H printers.

Update March 15, 2021

Despite various promises from AnyCubic – absolutely nothing happened. I still had a printer that would not work. In December they had the excuse of the pandemic and shortage of parts – then of course along came the Chinese New Year… but those excuses are no longer valid. Other companies can get things fixed and replaced.

AnyCubic have however, despite various promises, failed to provide any useful help (I should not have to mess with this or be expected to know how to fit replacement parts which as it turns out were not needed). Indeed mid-March 2021 I was about to simply throw the printer in the bin when I (amazingly) stumbled across a YouTube video which pointed me back to the Anycubic site, which by now had updates for the firmware. I went straight in, did the update and lo – the menus work. I also read one guy’s comments about having to increase the base layer time. So, with the menu issues largely out of the way and some confidence that there may be an issue with the base layer timing, I was ready to try again.

I came SO NEAR to scrapping this printer because Anycubic staff either have VERY poor English skills or simply cannot be bothered to help (or both). Thank heavens the general community are more helpful.

I’m still not sure at this point how to increase the exposure time for the first layer but as it happened the second problem was in fact incorrect factory alignment – the HOME position was not actually home, but a couple of mm off. I soon sorted that…. and…. I’m in BUSINESS.

Going back to the original demo file I found – the 6-way USB cable holders. As regular readers know, I’m quick to pull up faults in products – but I’m also equally quick to rave about great products!

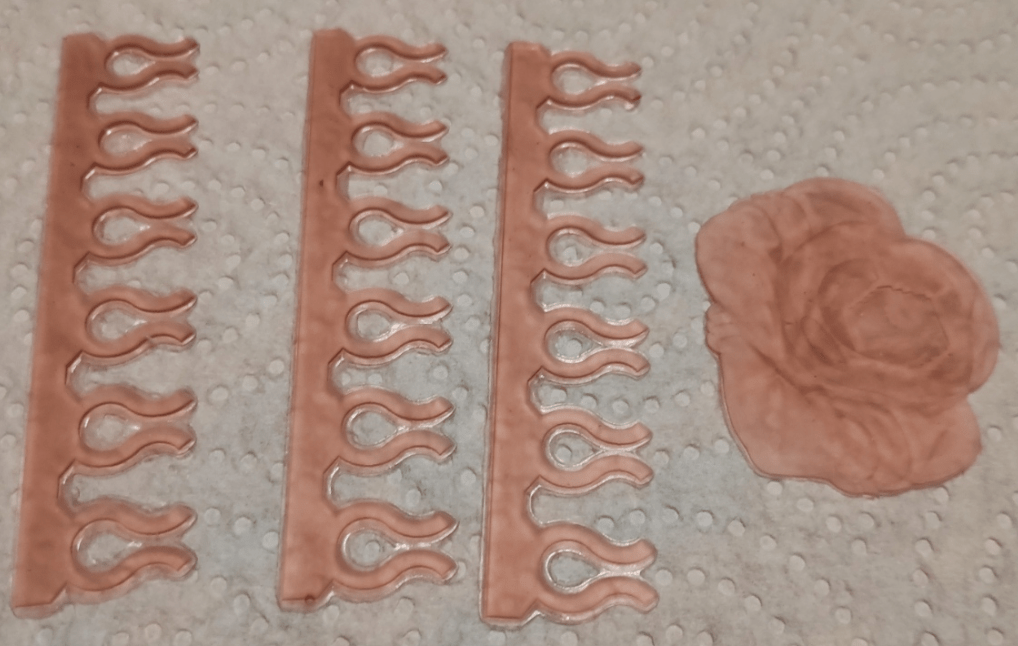

To the right, a photo of the Anycubic-Mono-produced USB cable holders – which would be as good as anything I could buy but for my choice of (somewhat brittle) resin (I should have learned about “shore hardness” and flexible resins before heading off to make flexible parts), using light blue water-based resin which I’ve described above.

Stop press: Chitubox 1.81 (stable) now supports the Anycubic Mono printer.

And here (6:30am Mar 16) is my first “success”, thanks to the updated Anycubic firmware, my slight adjustment of the HOME position, Chitubox 1.81 and Elegoo water-washable (clear blue) photopolymer resin…. my first 1mm thick “STITCH” – isn’t he lovely… I had some wine, set him off printing, went to bed and several hours later, there he was – a quick wash under the tap and he was done.

I do want to be perfectly clear, I did not design STITCH, he came off the web. Here are my settings, almost all defaults but I added a little “bottom” exposure time to ensure he stuck to the base (gut reaction after my first experience with the printer) and slightly reduced general exposure time (because the printing took AGES anyway and I’m impatient) but that’s it, I’d previously set hollowing to 1mm for this guy in Chitubox 1.7 and left that in place for my first use of v1.8.1 – if I can do this, you can. I had visions of his little feet breaking off as I (quite easily) removed him off the base with the supplied plastic spatula – but no… perfect.

Photography made possible with the aid of the VIJIM studio light I’ve also described elsewhere. For scale, STITCH is around 70mm high to the top of his ears, WELL within the capability of the printer.

As for the water-washable resin – worth it’s weight in gold. No more plate clogged up with resin, once I was done under the bathroom tap, everything looked like new.

Update March 28, 2021

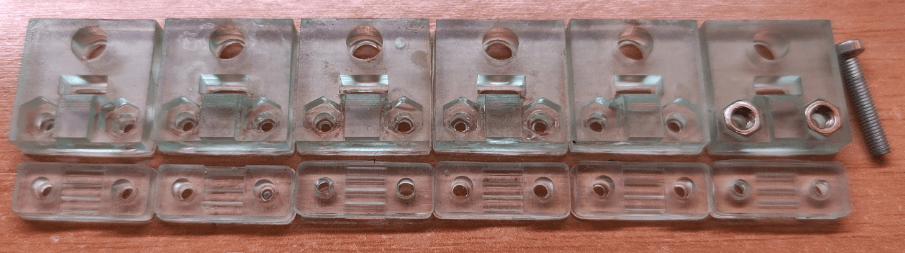

It gets BETTER. I’m busy working on a new version of the Eleksmaker A3 Pro Laser Engraver – and I happened to notice that the belt tensioners (perspex, held in place with a single bolt and using a small nut and bolt to force the belt to stay put) have not changed since their earlier model. Looking for a better solution I started to think I might make my own tensioners on a 3D printer. It didn’t immediately hit me but the resin printers can do this nicely. At that point, I thought (with my “Stitch” success), it could be worth taking another look at the Anycubic Mono. And I’m so glad I did.

Off I went to “Thingiverse” in search of a design for a replacement tensioner for the Eleksmaker – found a nice design – put the STL file into Chitubox 1.8.1 on my PC, hit copy/paste 6 times to make 6 copies of the same tensioner, hit “slice” and after making sure that Chitubox was set to the now supported Anycubic Mono, selected “all” and saved the resulting file to a memory stick which I then inserted into the Anycubic Mono printer.

I put some of my new water-washable Elegoo resin into the printer and hit the print button – 30 minutes later I was in business. The plate was holding onto my 6 new sets of tensioners (12 parts in all). I popped the plate into the bathroom sink which I’d filled with some warm water and a spot of liquid soap. I carefully removed all 12 parts using fingernails alone and gave them a good washing and drying. I should say at this point, no noticeable smell of resin at all and again using nothing more than soapy hands, I cleaned off the metal plate – nice and clean and shiny – a far cry from my first attempts a few weeks back.

I left the parts overight on my bench and this morning… (I can’t finish the job as it is Sunday – no-where to buy 8mm long M3 bolts and matching nuts) but I’m happy with the results – a set of 6 clear tensioners.

I still think the printer menu touch response could be improved (Crealty menu handling is better) but I’ll put up with that given recent fast, quality results.

And there’s more:

A major issue I have in my office is lack of holders for screwdrivers and other tools – I’m out of working space and need to get tools onto the wall. Typically at the hardware stores here I can find complete storage solutions but not simple wall holders for tools – enter the Anycubic Photon Mono, Elegoo water-washable clear blue resin and Thingiverse….

The Resin printers typically have size restrictions but I managed to get a pair of 4-way tool holders onto the plate (you can see the size from my (large) hand in the background. 1.5 hours each pair and another two on the way right now – no smell, no wasted material and they are rock solid. Not even remotely amateur-looking either.

I’m not entirely sure of the Banggood connection to this particular design – but here it is – all credit to the person who made this simple design. No supports needed – just straight off the Anycubic printer and into the sink for a quick wash then onto my wall where they will likely outlast me. And now, I need more resin.

Update July 2023

Well, things have moved on and AnyCubic have better printers out – but I still have my Photon Monp and now that I know a LITTLE more about resin printers, it seems the base exposure and contact area are more important than I first thought. I’m generally using water-washable resins these days as I got sick of having sticky hands and bench etc. It is important to ensure the model is flat on the bottom – the bit that will attach hopefully) to the gantry – if you don’t get that right, it’ll attach to the bottom of the vat and that’s the end of your model. I’m currently working with a printer from Geeetech and after messing up a model, I was a bit rough cleaning the mess off the FEP sheet and damaged it irreparably – thankfully a complete replacement vat with sheet pre-fitted was only maybe 12 Euros or less and I managed to get one FOC.

I learned from that and when today I tried printing a Warhammer model on the Anycubic (I chose a non-even side for the base with very little contact area – bad mistake), I was very careful with the spatula when scraping the wasted material from the FEP sheet. No harm done. Attempt 2 (turned 90 degrees) is underway and I took the opportunity to add in another couple of models – after all, no additional model height means no additional processing time. Wish me luck.

i had the same thing and did quit. 3 flat biscuits. 2years later im trying again. i cant even get the test print file to load this time, the original usb is long gone and i cant understand how to get it to register on the printer.

so distressing i want to chuck the thing in the bin.

how to I get the ,pwmo format back?

Hi Peter. Thanks for the detailed post.

I too bought recently a Photon Mono and am also having trouble printing with it. I have tried about 6 prints. First one was the test cube provided by Anycubic and it printed perfectly. Then I tried to print a warhammer tank and it did not stick to the plate so I had to cancel after 2 hours. I added some supports in the slicer and tried again, this was my 3rd print and it also fell from the plate so another failure. As my 4th print I printed again the test cube just to check if there was something wrong but it printed perfectly again. For 5th and 6th prints I have been trying to print a Darth Vader mini from thingiverse and the printer does some very weird thing: at 3 random points it prints 3 whole thick planes of resin that ruin the whole figure and waste a ton of resin. I repeated the print because at first I thought it was because I paused the print 3 times but it did the same on the last time I tried. I guess there is something wrong with the 3d model but it doesn’t show anything like these weird planes in the STL or the PWMO files. Now as I write this I am trying a 7th print (fingers crossed), this time I found a much simpler and smaller model and I rotated it 90º to add supports everywhere. Have you tried something like that? Rotating the model and add plenty of supports so the model stands entirely on them? It seems to be one of the advices people often give on the internet for resin printing.

Thanks!

P.S. Great blog! 🙂

Thanks for the feedback – really appreciated. Every single time I print on my Crealty – the model sticks to the plate – and works a treat – every single time I try to print with the AnyCubic – all I get is a very thin sliver of material. I’m about to give up – between that and the touch screen which seems quite unreliable – AnyCubic replied and said they’d send out spares but nothing has arrived – they should just send out another printer rather than have me hassle with it. I’m so pleased with the Crealty I plan to test the LD-002H (with WiFi) next – no-one can say I’ve not tried hard, nice to know I’m not the only one having issues with it. I’m using the same files on each printer so nothing wrong with the STLs I would imagine.

If you magically get yours to work do let me know in here so I can help others.

Regards

Pete

Hi Peter, thanks for the message! My 7th print finally worked. I just found a “kiwi” (the NZ animal) model out there and reduced it to a very small size on the slicer, then turned it completely on its side and added a few supports. The print worked but I am not entirely satisfied because there were a few artifacts and most annoyingly there was some kind of thin resin foil that had curated near the base and I had to be careful when removing together with the bases. I’ll try to upload a pic to this message. I am worried that this kind of resin foil will ruin other prints so I will try to print a larger version of this design too. About your trouble, if no model sticks to the base maybe it’s just a calibration issue? Have you tried printing the test cube?

Thanks!

Still nothing from AnyCubic..

Good grief – that was fast – I’ve only just put this entry up – fixed thanks to your eagle-eye.

Pete

You seem to have mixed up the car Proton with the printer Photon.